ADAM FABRIWERK P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ADAM FABRIWERK P.LTD.

Blending Vessels

Pharmaceuticals

Sterile Solutions

Vial

Ampoules

I. V. Fluids

Aerosols

LVP & SVP Solutions

Biopharmaceuticals

Vaccines

Human Insulin

Serums

Plasma Fractions

Bacteria and cell cultures

Bottom mounted Magnetic mixer with speed variation from 50 to 350 RPM

Flush Bottom Outlet value (Zero Dead Leg)

Sterile Flange Connections for Top dish nozzles to enhance CIP, SIP operations

pH sensing through sanitary knuckle port on vessel shell

Conductivity sensing through sanitary knuckle port on vessel shell

Temperature sensing through sanitary knuckle port on vessel shell

Load Cells for weight measurement

Vessel with CIP / SIP able accessories

PLC-based, with Touch Screen MMI and SCADA Packages

Vessels are designed in accordance with ASME BPE Guidelines

Flush bottom outlet value

Zero dead leg design

Valve diaphragm clamped between valve body and actuator

Both value housing and piping connections are free draining

Reliable for CIP and SIP operations

Capacity: Processing Batch sizes from 5 litres to 30000 litres

Key Benefits

Cost Effective solution for complete range of sterile liquid products

Magnetically powered drive, no seals, no shafts, thereby eliminating possibility of contamination

Low Power Consumption compared to conventional agitation systems

Ability to mix till the last drop

Low Shear Forces (less damage to product)

Cip Modules

CLEANING IN PLACE (CIP) Module is the process used to ensure that, process reactors, vessels and lines are free of organic and inorganic contaminants:

Pharmaceuticals

Sterile Solutions

Vial

Ampoules

I. V. Fluids

Aerosols

LVP & SVP Solutions

Biopharmaceuticals

Vaccines

Human Insulin

Serums

Plasma Fractions

Bacteria & cell cultures

CIP cycles can be subjected to the following process machinery

Fermentors

Blending Vessels

Media / Harvest / Storage / Filtration Vessels

Transfer Lines

Process Equipment

Completely Automated Process Cycles

On line display of process parameters with P & I of Operating Systems

Display of Fault messages

Supervisory access code prevent unauthorized changes

Detergent / Acid / Alkali dosing

On Line pH, Conductivity, TOC Sensing

CIP is designed in accordance with ASME BPE and EHEDG guidelines

PLC-based, with Touch Screen MMI and SCADA Packages

Spray device characteristics

The cleaning liquid turns the spray head by means of a specially positioned nozzle

Rapid repitition impact loosens the dirt and washes it off the tank surface

The cleaning effects is optimum at low pressure in small to medium size tanks

With increasing pressure, the rotation speed gets higher, while due to stronger atomization, the reach of the spray gets lower

Operation at the optimum pressure ensures required cleaning results and avoids wear of the nozzle

Effective Cleaning Criteria Factors include

Cleaning Cycle Time

Cleaning Agent and Temperature

Concentration and Chemistry of the Cleaning Agent within the circuit

Degree of Turbulence of the Cleaning Solution

Characteristics of the surface being cleaned

Spray Device Selection (Static Dynamic)

Key Benefits

Validatable process for Sterilization of process equipment

Lower Facility Operating Costs

Minimal dismantling of equipment and piping

Reduced turnaround time for cleaning

WFI requirement for cleaning reduced significantly

Exposure to hazardous activities or entry into tanks, is eliminated

Liquid Oral Processing Systems

- Oral Liquids

- Suspensions

Process Operations For:

- Material Handling and Transfer

- Sugar Syrup Preparation

- Sugar Syrup Prefiltration

- Solution Preparation

- Solution Storage

- Platform Structure

- Transfer Panels

- CIP System

- Automation

- Raw Material Storage

- Inverted Sugar Storage

- Liquid Glucose Storage

- Glycerin Storage

Solution Storage

- Storage Vessels

- Bottom Entry Propeller Mixer for vigorous MASS MOVEMENT within the vessel

- Lug Mounted Vessel on Platform with Load cells

Sugar Transfer

- Sugar can be transferred through a vacuum system

- Transfer is directly into the Sugar Dissolution Vessel

- Chances of Contamination due to handling greatly reduced

- Process Vessel rated for Vacuum

Inverted Sugar/Glucose Transfer

- Inverted Sugar can be transferred through a twin/tri lobe pump

- EHEDG/3A approved Twin Lobe pumps used

- Transfer is directly into the Sugar Dissolution Vessel

- Transfer Line for Liquid Glucose Transfer is Electrically Heat traced and

- Insulated to maintain the temperature at 60 deg C for EASE of transfer of liquid glucose

Sugar Syrup Preparation

- Jacketed/Insulated/Cladded Vessel

- Bottom Entry Propeller Mixer for vigorous MASS MOVEMENT within the vessel

- Lug Mounted Vessel on Platform with Load cells

Solution Preparation

- Jacketed/Insulated/Cladded Vessel

- Bottom Entry Propeller Mixer for vigorous MASS MOVEMENT within the vessel

- Bottom Entry High Shear Mixer for vigorous CUTTING ACTION within the vessel

- Lug Mounted Vessel on Platform with Load cells

Solution Filteration

- Zero Hold up filter press

- Vessel with number of horizontal plates

- Plates are unitised with Tie Rods at the centre and the periphery of the stack

- Fluid flow is from outside of the plate stack,through spacing between the plates and then through filter media

- Filter media can be filter sheet or filter cloth

Cream And Ointment Processing Systems

Designed for the Process With long experience at the leading edge of vacuum processing, Adam Fabriwerk has developed a system which addresses the fundamental requirements of the served markets, including.

The principal applications for the system are in the pharmaceutical and premium cosmetics sectors.

Flexible process parameters setting

Variable shear force adjustment

Easy to upgrade to reflect the latest processing trends

Pharmaceuticals

Lotions

Creams

Gels

Ointments

Biotech products

Cosmetics

Cold creams

Emulsions

Lotions

Gels

Mascara make-up

Shampoo

Toothpaste

The easy-to-use Mixer control package can incorporate process parameters storage for simple and fast set-up.

- Heating / cooling and insulated jackets complete with temperature control and safety equipment

- Semi Contra Rotary agitator with open slot scraper design

- Short loop product Re-Circulation for smaller batch sizes

- Hydraulic lifting on manufacturing vessel top dish to facilitate product recovery

- Separate pre-mix vessels for wax and water phase

- Process piping with transfer panel design for automated plants

- Cleaning In Place cycles with validation protocols

Vessel Design

Extensive research & development has produced the best combination of vessel and agitation system, offering high productivity, quality and yield.

- Low relative batch size

- Conical design and proven geometric ratios ensure optimum Product flow

- All surface angled to ensure ease of cleaning

- Reliable for CIP and SIP operations

Integrated Vacuum System

- Fully controllable to permit variation of vacuum levels according to the process phase

- Operators on demand for environmentally friendly and low cost Operation

- Vacuum line can be fully flushed for sanitation purposes

- Reliable for CIP and SIP operations

User Friendly Interface

The easy-to-use Mixer control package can incorporate process parameters storage for simple and fast set-up.

- PLC-based, with Touch Screen MMI and SCADA Packages

- Choice of packages to suit application requirements

- Flexible Configuration

Processing Options

A comprehensive range of additional features can be provided to increase the flexibility of the Mixer. Each option is supplied fully integrated into the control system of the unit with appropriate safety features.

Modular Construction

The design of the Mixer enables users to tailor the installation to their requirements. Units can operate on a standalone basis or as part of an integrated system. The core components of every Mixer are:

- Process vessel with a choice of agitation systems

- Vertically, bottom mounted high shear head

- Internal and external High Shearing

- Vacuum generation and control

- User-friendly interface

High Efficiency High Shear Head

The hearts of the Mixer is the vertically mounted, bottom high shear head, which introduced shear, drives product flow and discharges the completed batch.

- Aseptic construction

- Variable shear force adjustment

- No additional pump required for discharge and cleaning

Capacity

capacity 5 to 10000 kgs

Key Benefits

- Highly efficient processing with significantly reduced batch times and operating costs

- Pre-stored process parameters give high batch-to-batch consistency

- End products are stable, glossy and air-free with a consistent specific weight for improved filling performance downstream

- Flexibility: one machine with the capability to manufacture a wide range of products

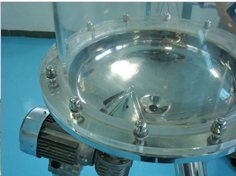

200L Blending Vessel

Description / Specification of 200L Blending Vessel

We are involved in offering a wide range of 200L Blending Vessel to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of 200L Blending Vessel. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

100L Filtration Vessels

Description / Specification of 100L Filtration Vessels

We are involved in offering a wide range of 100L Filtration Vessels to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of 100L Filtration Vessels. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Magnetic Mixer

Description / Specification of Magnetic Mixer

We are involved in offering a wide range of Magnetic Mixer to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Magnetic Mixer. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

50 Kgs Automated Cream Mixer

Description / Specification of 50 Kgs Automated Cream Mixer

We are involved in offering a wide range of 50 Kgs Automated Cream Mixer to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of 50 Kgs Automated Cream Mixer. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.